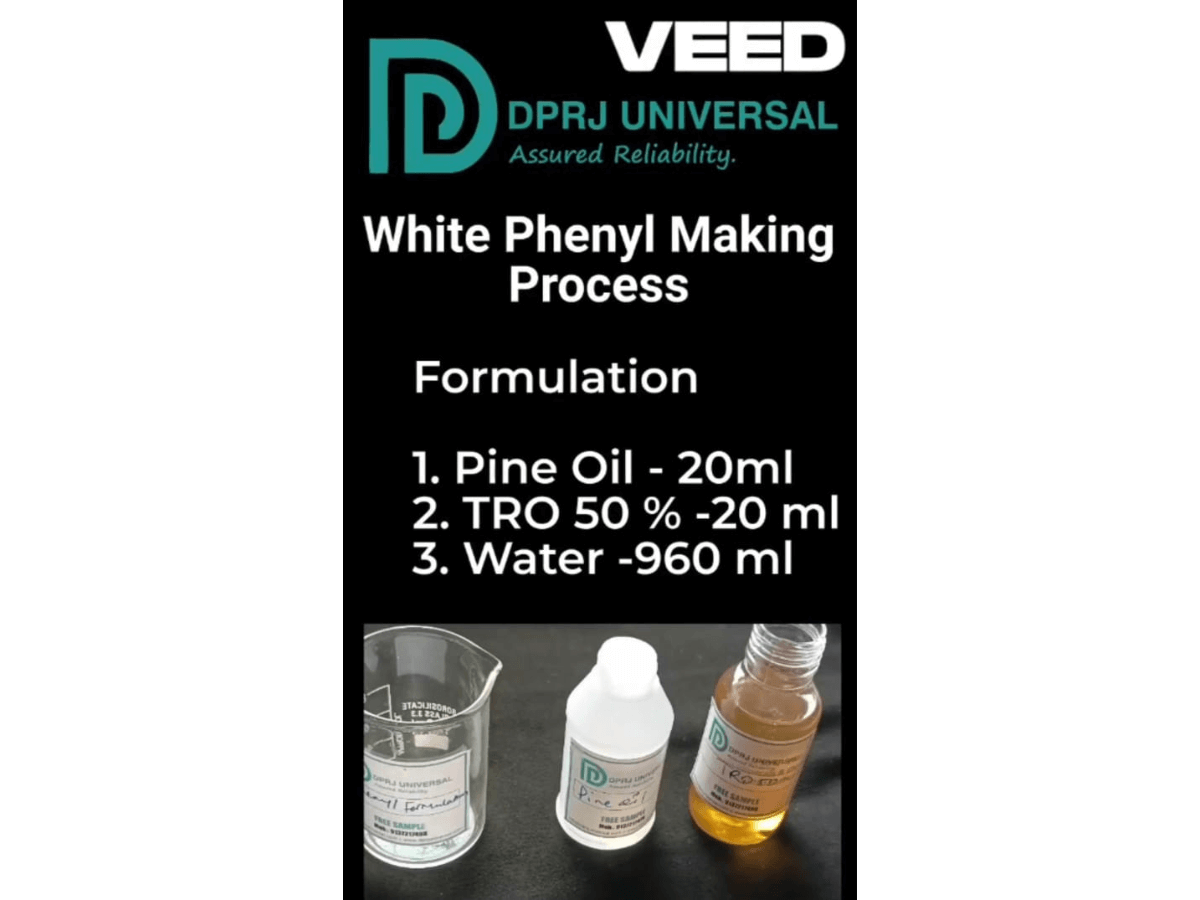

Video Guide: Mixing 1 Liter of White Phenyl Concentrate

Watch the quick mixing process using Pine Oil, TRO, and Alphox-200 to achieve a stable, high-quality white phenyl concentrate.

What is “White Phenyl”?

White phenyl is a pine-oil based floor disinfectant and deodorizer commonly used in India. It’s a surfactant-stabilized, diluted pine oil product with a characteristic scent and disinfectant properties. This pilot recipe produces a typical liquid cleaner concentrate—suitable for testing at small scale. Always follow local laws for production and sale.

Bulk White Phenyl Raw Material Supply

As a leading manufacturer and supplier, we provide all the critical components for your white phenyl concentrate formulation directly to your facility. Check our competitive prices for these key white phenyl raw materials:

Key Ingredients for a Stable Emulsion:

Ingredients (Recommended Starting Formulation)

This table outlines the recommended starting formulation for a concentrated phenyl product, measured by weight (w/w). Tweak these percentages after stability testing to achieve your desired white phenyl concentrate formulation.

| Ingredient | % w/w | Function |

|---|---|---|

| Water (demineralized) | ~85.0% | Diluent/Main Base |

| Pine Oil 32% active | 5.0% | Disinfectant & Scent Base |

| Tro (anionic surfactant) | 6.0% | Cleaning, Foaming & Emulsion Aid |

| Alphox-200 (nonionic co-surfactant) | 1.5% | Solubilizer & Emulsion Stabilizer |

| Cosmetic / masking fragrance | 0.2% | Scent (Optional) |

| Preservative / biocide | 0.1% | Shelf Life (Optional) |

| Dye / whitening opacifier | 0.2% | Appearance (Optional) |

| pH adjuster (citric acid or soda ash) | trace | Required for pH 6.0–7.5 |

| TOTAL | 100% |

Note: Use supplier recommendations for Tro and Alphox concentrations. Ensure compatibility by consulting your chemical supplier.

Example Pilot Batch — 20 L (Approx. 20 kg) Quantities

This calculation helps define the exact white phenyl raw material quantities needed for a small, 20-litre test batch.

| Ingredient | Quantity (Approx.) |

|---|---|

| Water | 17,000 g (17 L) |

| Pine Oil 32% | 1,000 g (1.0 kg) |

| Tro | 1,200 g |

| Alphox-200 | 300 g |

| Fragrance | 40 g |

| Preservative | 20 g |

| Dye/Opacifier | 40 g |

Step-by-Step Manufacturing Procedure (Small Batch)

Equipment & PPE

- Clean mixing vessel (stainless steel or HDPE) with gentle agitation (propeller stirrer or paddle).

- Graduated balance or scale accurate to 1g.

- PPE: nitrile gloves, safety goggles, apron, good ventilation. Fire extinguisher nearby.

- Preparation & Safety Check: Ensure workspace is ventilated. Wear PPE. No open flames. Pre-weigh all ingredients accurately.

- Fill Water (Aqueous Phase): Add 85% of total demineralized water into the mixing vessel at room temperature 15–30 C. Begin gentle agitation.

- Dissolve Surfactant (Tro): Slowly add Tro (anionic surfactant) to water with agitation. Mix until uniform and slightly translucent. This step prevents lumps and sets the stage for emulsification.

- Add Alphox-200 (Nonionic Solubilizer): Add Alphox-200 slowly while stirring. This co-surfactant helps solubilize the Pine Oil and stabilizes the final emulsion.

- Incorporate Pine Oil: Slowly add Pine Oil 32% active over 2–5 minutes, maintaining agitation. The mixture will quickly emulsify. Continue mixing for another 5–10 minutes to ensure complete dispersion of the oil phase.

- Add Preservatives, Fragrance, Dye: Add preservative (if used) and fragrance. Incorporate the dye/opacifier (premixed with a small water portion if necessary). Continue mixing until homogeneous.

- Adjust Volume and pH: Add the remaining water to bring the batch to the target volume. Measure pH—aim for pH 6.0–7.5 (mildly neutral). Adjust with small amounts of citric acid or soda ash if necessary.

Product Testing & Quality Control

Always perform these checks immediately after mixing and during storage:

- Visual: Uniform white liquid, no free oil layers, color consistent.

- Stability Quick Test: Pour a sample into a jar and leave for 24 hours at ambient temperature—no phase separation or creaming should appear.

- pH: Must be within the target range 6.0–7.5.

- Density: Record for batch control.

Safety & Handling (Mandatory Manufacturer Guidance)

- Do NOT mix with bleach (sodium hypochlorite) or strong acids—this can release hazardous gases.

- Keep away from ignition sources.

- Provide an SDS (Safety Data Sheet) for the finished product.

- Train all staff on proper spill response, PPE use, and first aid.

IMPORTANT FORMULATION NOTE

The white phenyl making process differs according to individual preferences. The information given above is based on our general experience but due to many variable factors beyond our control (such as water quality, equipment, and raw material batch variations), we do not guarantee the results in formulations adopted by users.

Users are informed that they should evaluate in their formulations as per their requirement. We strongly recommend testing every batch before commercial use.

Ready to Scale Your White Phenyl Business?

Partner with us, a reliable white phenyl raw material manufacturer and supplier. We offer guaranteed quality on Pine Oil, TRO, and Alphox-200, along with technical support for scaling your white phenyl concentrate formulation.

🚀 Request Bulk Pricing & Technical Support